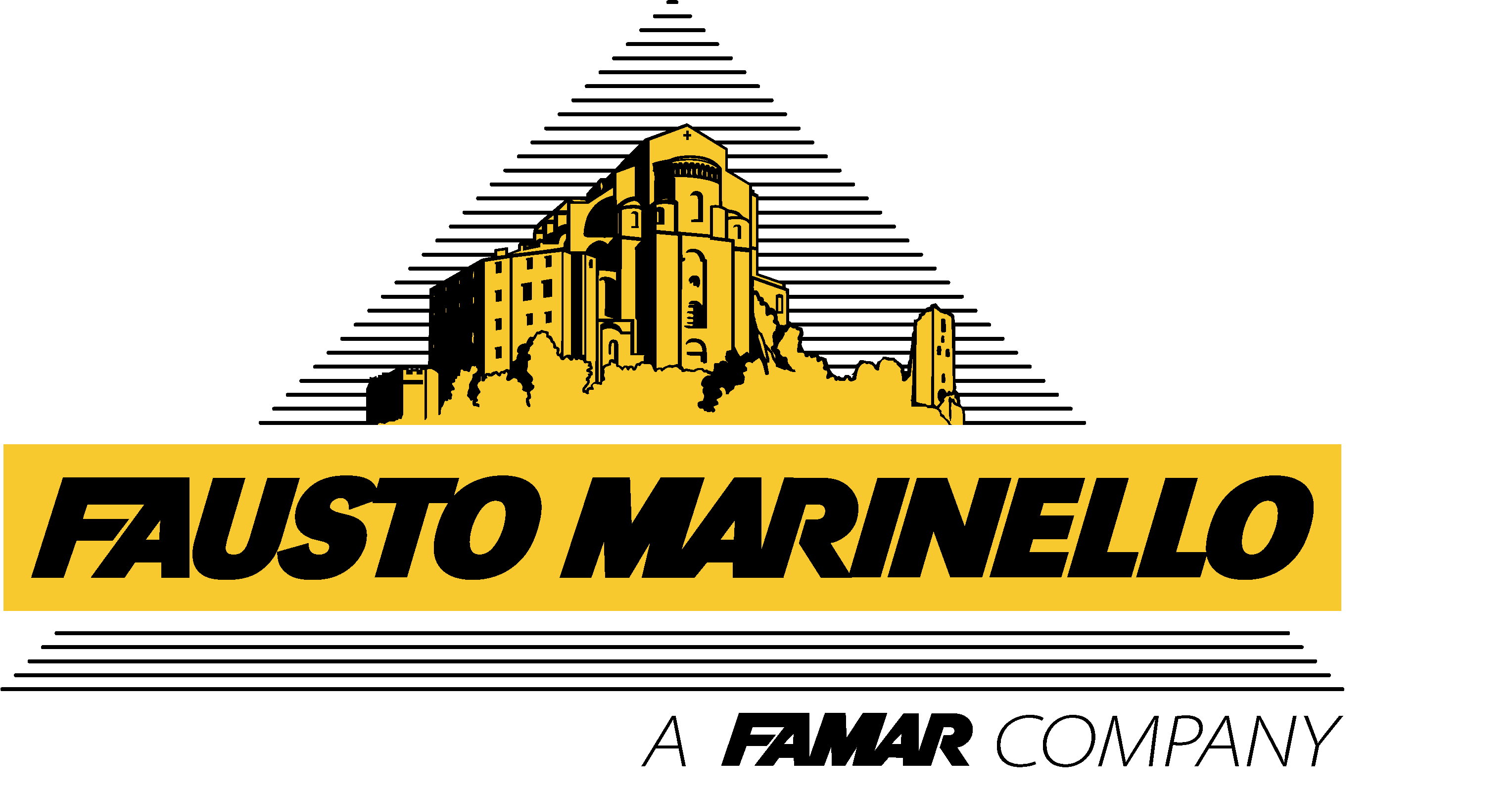

Descrizione:

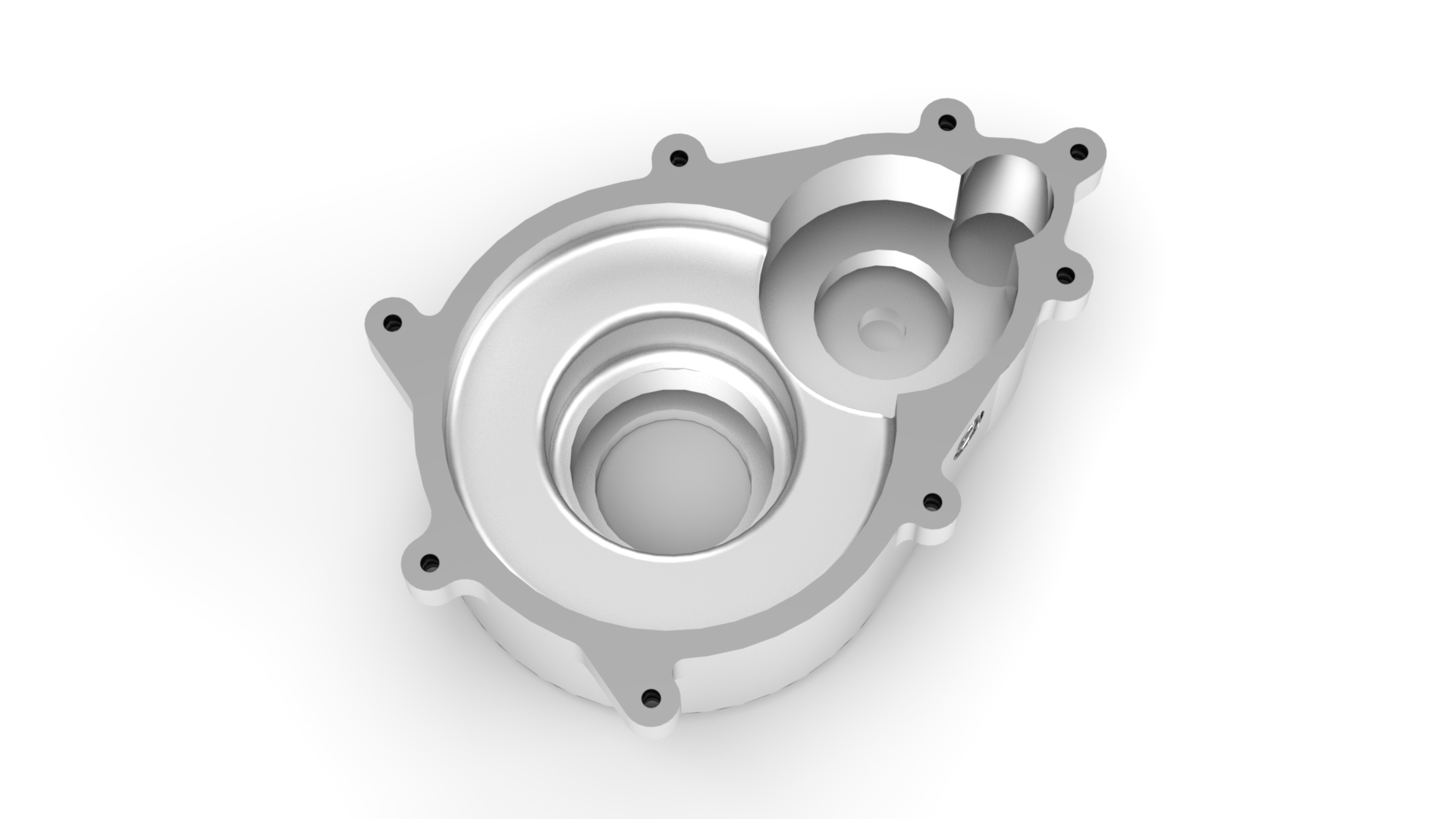

Il tornio verticale Fausto Marinello FM 26 è indicata come la soluzione migliore per numerose tipologie di lavorazione, partendo dalla tornitura e raggiungendo la foratura, la fresatura, la dentatura e la rettifica, tutto in una sola macchina. L’efficacia della famiglia Ergo è osservabile durante tutta la vita macchina con performances e sicurezza di lavorazione sempre ad altissimi livelli. Completa personalizzazione e estrema adattabilità ai più differenti cicli di lavorazione rendono questa macchina utensile il partner ideale per la tua azienda.

EFFICIENCY

EFFICIENCY

Highest production and machining precision, fully available machining area, 3” seconds tool change, pallet changer with c and w axes (5th axis) optional, single spindle series with optional single or double rotary table suitable for machining of light alloys and nonferrous materials, speed above 120 m/min and acceleration above 2g

QUALITY

QUALITY

Record-breaking compactness, closed bedframe, box-in-box design, tools control system, maximum accessibility to machining and loading/unloading area outstanding dynamism (acceleration, jerk and high kv values)

EASE TO USE

EASE TO USE

Extremely accurate pallet positioning, clamping equipment with direct fluidic inlet, ease and safe fixture changeover, easy cleaning of all internal areas

FLEXIBILITY

FLEXIBILITY

Customized solutions with highly efficient and flexible automation, fully customizable control panel, extremely low space requirements

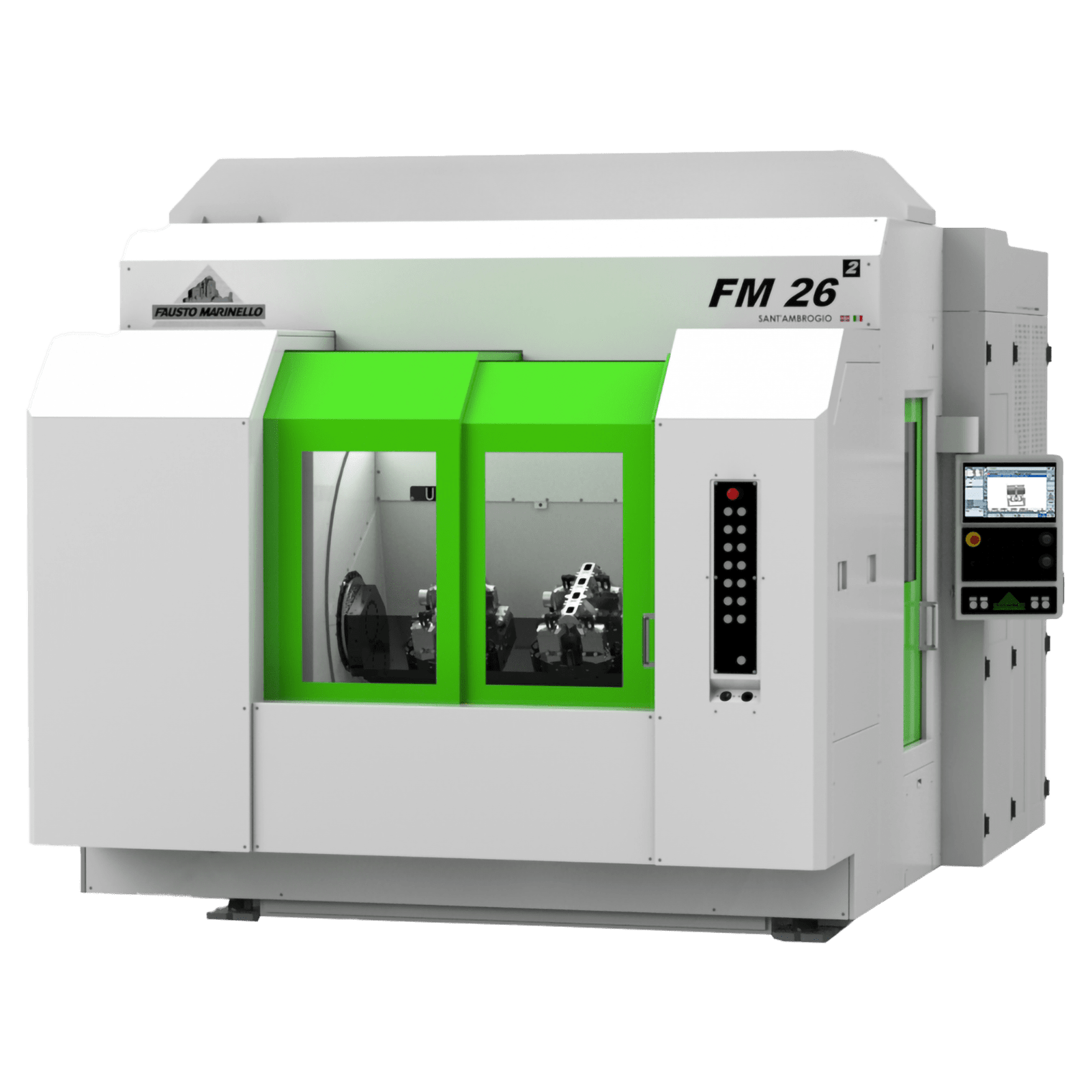

Technical file:

Spindles |

|---|

2 |

Spindle distance |

|---|

590-651 |

HSK attachment |

|---|

HSK-A63 |

Power (per spindle) |

|---|

32 kW |

Speed range |

|---|

1-17.500 rpm |

Torque (per spindle) |

|---|

80 Nm |

X-axis machining stroke |

|---|

600 mm |

Max. speed X |

|---|

120 |

Y-axis machining stroke |

|---|

700 mm |

Max. speed Y |

|---|

120 |

Z-axis machining stroke |

|---|

550 mm |

Max. speed Z |

|---|

120 |

4th axis diameter |

|---|

Ø750×1500 mm |

Spindle versions

HSK-A63-14000RPM-181Nm

HSK-A63-20000RPM-123Nm

HSK-A80-14000RPM-181Nm

HSK-A100-12500RPM 200Nm

Tool stocker options

HSK-A63

2×42

2×72

2×108

HSK-A80

2×35

2×60

2×90

HSK-A100

2×28

2×48

2×60

Options

TOOL ATTACHMENT FLUSHING IN THE STOCKER AREA

TOOL IDENTIFICATION SYSTEM

MIST SUCTION FOR MACHINING WITH COOLANT

HIGH PRESSURE PUMP

COOLING UNIT TO CONTROL COOLANT TEMPERATURE

ELECTRONIC HANDWHEEL

DRILLTIP PRESENCE PROBE CONTROL SYSTEM

GAGE

3 COLOR LIGHT COLUMN

OIL SKIMMER

LASER TOOL BREAKING MONITORING SYSTEM

PRESETTING LASER FOR TOOLS

FIXTURE WASHING SYSTEM

CHIPS MANAGEMENT PREMIUM PACKAGE

Mandrini |

|---|

2 |

Interasse |

|---|

590-651 mm |

Corsa Asse X |

|---|

600 mm |

Corsa Asse Y |

|---|

700 mm |

Corsa Asse Z |

|---|

550 mm |

Potenza Mandrino |

|---|

32 kW |

Coppia Mandrino |

|---|

80 Nm |

Interfaccia HSK-A |

|---|

HSK-A63 |

Velocità |

|---|

1-17.500 rpm |

Velocita in Rapido Asse X |

|---|

60 m/min |

Velocita in Rapido Asse Y |

|---|

60 m/min |

Velocita in Rapido Asse Z |

|---|

60 m/min |

Ø 4° asse |

|---|

Ø750×1500 mm |

Scheda Tecnica:

Mandrini | 2 mm |

Interasse | 590-651 |

Interfaccia HSK | HSK-A63 |

Velocità | 1-17.500 rpm |